Borescope inspection training has evolved

- Claudia Ouellet

- Jan 17, 2024

- 2 min read

How we developed that skill in aircraft maintenance engineers doesn’t work anymore.

How useful is “Here’s the hole, here’s the scope, this is the inspection procedure we use, look at what I’m doing and try to do the same.”

Something is missing, and it’s huge.

Your people need to make significant decisions during this inspection. Some are easy.

Some are not.

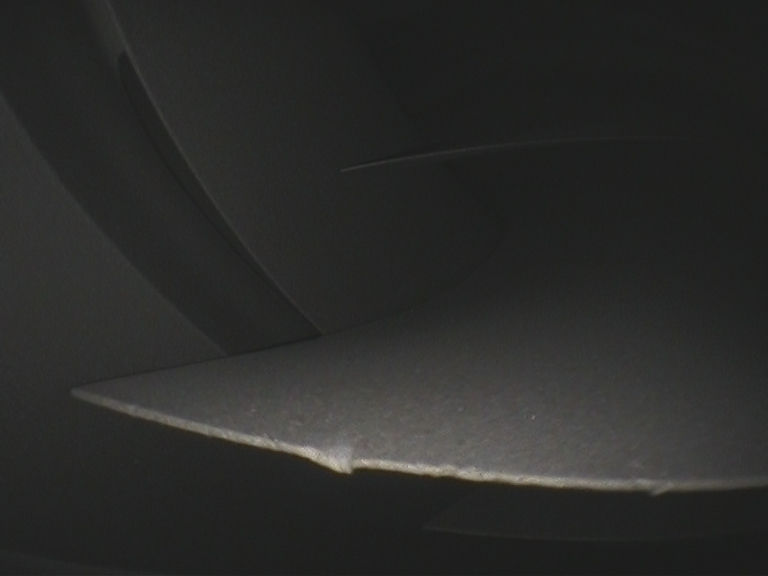

There are very difficult questions to answer during an inspection; there's pressure. Do you take the engine off the wing or not? How critical is this damage? Is this within tolerance? How do you correctly interpret the manufacturer’s criteria? How can you expect this situation to progress? Do you waste good hours by taking the engine off right now, or do you take too much risk by leaving it on?

In short, how can you help mechanics develop their critical decision-making skills for borescope inspections?

It’s challenging, and you need to train them for it explicitly.

The traditional way to do this is to give the basic borescope inspection training and wait for the mechanics to gain experience through trial and error and some coaching. It’s a tried-and-true method, and it gets results. But when? And when do you need your team to be proficient: a few months or years from now, depending on how often they practice their new skills? Or yesterday, as with most things in aviation?

Modern borescope training must develop the participants’ critical decision-making skills, not just their endoscopy capacity. So, you have to make them practice making good decisions repeatedly with real-life scenarios and practical exercises. It gets you solid results (way) faster.

And what are those results exactly? What happens to your business when your mechanics are good at making difficult decisions during borescope inspections?

Operational flexibility: you can organize your teams and off-base missions more freely, knowing you have more evenly distributed expertise.

Costs management: you don’t waste engine hours.

Safety: you get sound decisions from your team.

Independence: you can manage your operation without waiting for outside help.

We don’t know about you, but that’s music to our maintenance management team’s ears.

Comments